Validation is a critical step in the development of any remelt simulator. In addition to having accurate thermophysical property and boundary condition data, accurate furnace characteristics (bus resistance, power factor in ESR furnaces, base contact resistance) are also necessary to achieve correct results. ESRsim, SLABsim, and VARsim all utilize alloy-specific, temperature dependent thermophysical properties, and temperature dependent boundary conditions.

Both ESRsim and VARsim have been used to simulate a number of ingots comprised of a variety of alloys in different sizes as part of the validation procedure. SLABsim has received more limited validation due to a scarcity of published data.

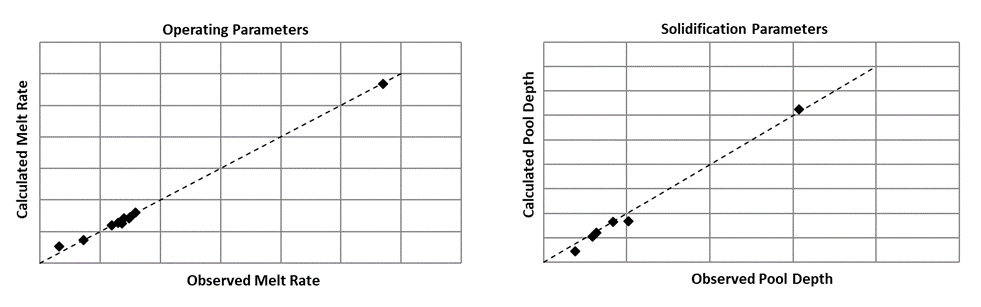

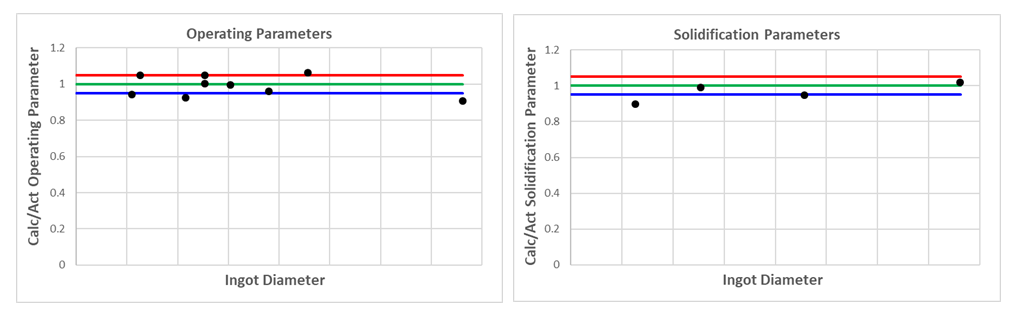

Plots of calculated operating parameters and solidification parameters for a variety of VAR melted alloys (4340, 718, Waspaloy, C300, and M-2) of different ingot diameters generally show good agreement with observed values.

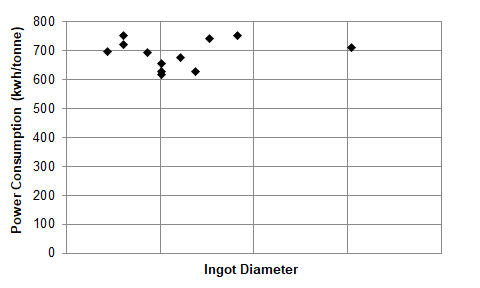

In all cases, the calculated specific power consumption is in the range of 600-800 kWh/tonne which is in agreement with generally expected values for VAR.

The error between calculated and actual operating and solidification parameters is estimated to be +/- 5% in comparisons with present production practices.

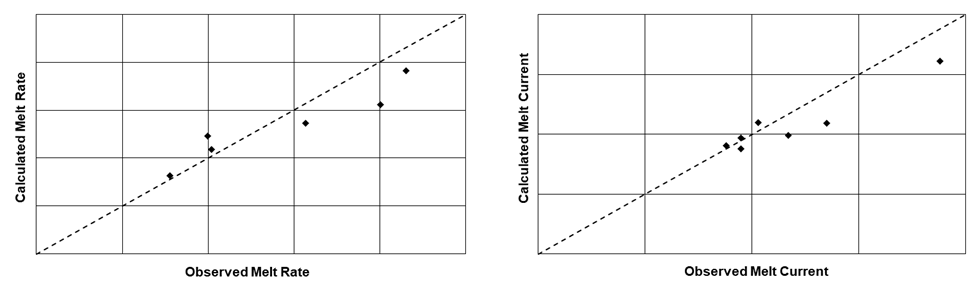

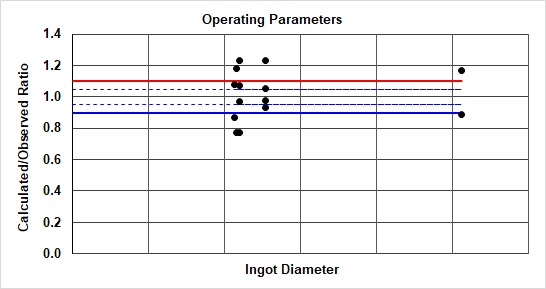

Validation of ESRsim presents more of a challenge due to several factors. In addition to uncertainty in slag thermophysical properties, variation in the specified temperature distribution in the slag due to varying current paths, and inconsistent furnace resistance due to variations in base contact combined with the inclusion of a power factor all introduce more sources of uncertainty. Despite these factors, results for a variety of alloys (718, 600, Waspaloy, 706) in different sizes generally show reasonable agreement between calculated and actual melt parameters. It is quite likely that better agreement could be obtained by inclusion of the correct, specific furnace characteristics.

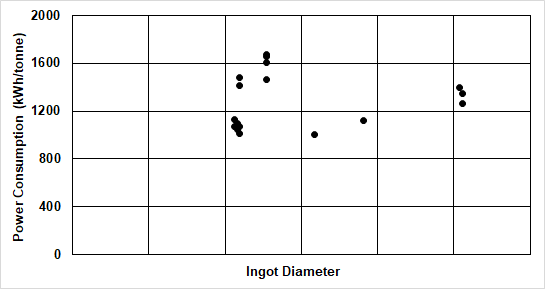

Calculated specific power consumption falls within the range of 1000-1400 kWh/tonne which reflects generally accepted values.

Due to the aforementioned uncertainties, the margin of error in the ESR calculations is probably in the range of 5-10%.

It is important to note that the simulations which led to the aforementioned results were all conducted with the same set of boundary conditions. While better agreement between calculated and observed values may have been achieved by adjusting these conditions particularly for ESRsim, unless there is a valid argument for doing so, this would defeat the purpose of having a simulator with universal applicability to a wide range of melting scenarios. Despite these uncertainties in the specific simulator predictions, the results can afford useful insights in showing trends and highlighting which factors are of most significance.