SLABsim is a rectangular ESR process simulator which incorporates operating parameters and furnace characteristics into electrode, slag, and ingot models to yield a tool suitable for simulating the remelt process from start to finish. Basic input data are expressed in terms of operating parameters (voltage, current, swing depth, slag weight, etc), heat-specific process parameters (electrode and crucible dimensions) and furnace characteristics (resistance, water temperature and flow, power factor, etc). The use of boundary conditions having default values, combined with menu-specified output parameters means that the simulator can be used by a process engineer having little to no modelling background.

A template of a SLABsim data file can be generated from within SLABsim by selecting the Create Data Template button. This will display the following menu to permit selection of units and other process parameters. Additional input data will be generated automatically.

The resulting data file will be applicable for remelting a nominal 9 x 37 in (235 x 940 mm) slab electrode of Alloy 718 into a 12 x 42 in (310 x 1075 mm) slab ingot using a 60F/20/0/20 slag.

Parameters designated by a ‘-1’ invoke a default boundary condition which has been determined based on the simulation of a variety of test cases, but which can be over-written if the user has more accurate data.

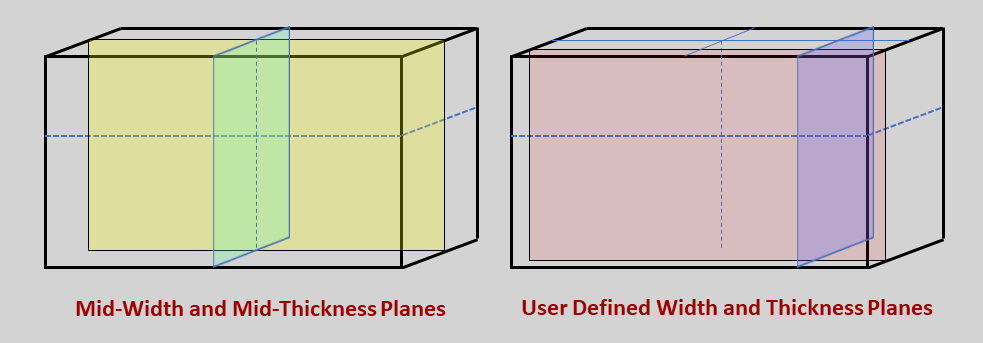

Results are presented for two sets of two orthogonal planes. The results for the central mid-width and mid-thickness planes are always displayed, results for two additional orthogonal planes, if specified as non-zero, are also presented.

Download SLABsim

To download the latest version of SLABsim (v 4.5.6) uploaded on 2025/11/01, please complete and submit the contact form below.